When it comes to modern rail transformers, epoxy potting is essential to reliably protect the windings. The low material coverage between the resin and the iron core presents a major challenge for long-term stability and efficient thermal management. However, Wevo’s potting compounds have been specially optimised to meet these requirements: their high filler content reduces the thermal expansion coefficient and minimises cracking compared with standard products. This combination lowers stress within the composite as well as mechanical strain, thus ensuring the long-term integrity of the windings.

Epoxy resin potting compounds: electrically insulating and thermally conductive

The complete impregnation of the windings further promotes long-term performance. The epoxy resin potting compounds for high-voltage transformers are used together with an organic hardener that enables extended processing time of up to 90 minutes at 100 °C when potted under a vacuum. The process enables essential partial discharge resistance – preventing small electrical discharges within the winding – and therefore reliable insulation.

In addition to electrical stability, thermal properties are crucial to the reliability of modern transformers. Wevo’s thermally conductive potting compounds are specially optimised to allow efficient heat dissipation, even during short-term thermal peaks. The results are cooler windings under load, lower operating temperatures and support for long-term stability.

Flame-retardant epoxy potting resins with rail approval EN 45545-2

Excellent flow properties are also ensured, making the epoxy resins suitable for processing large transformer cores. For an efficient production process, the systems can also be easily homogenised, despite their high filler content.

The flame-retardant potting resins have been tested in accordance with rail approval EN 45545-2 and also meet UL 94 V-0 standards. They therefore fulfil the essential requirements for potting materials in rail vehicles and for use in technically demanding high-voltage transformers.

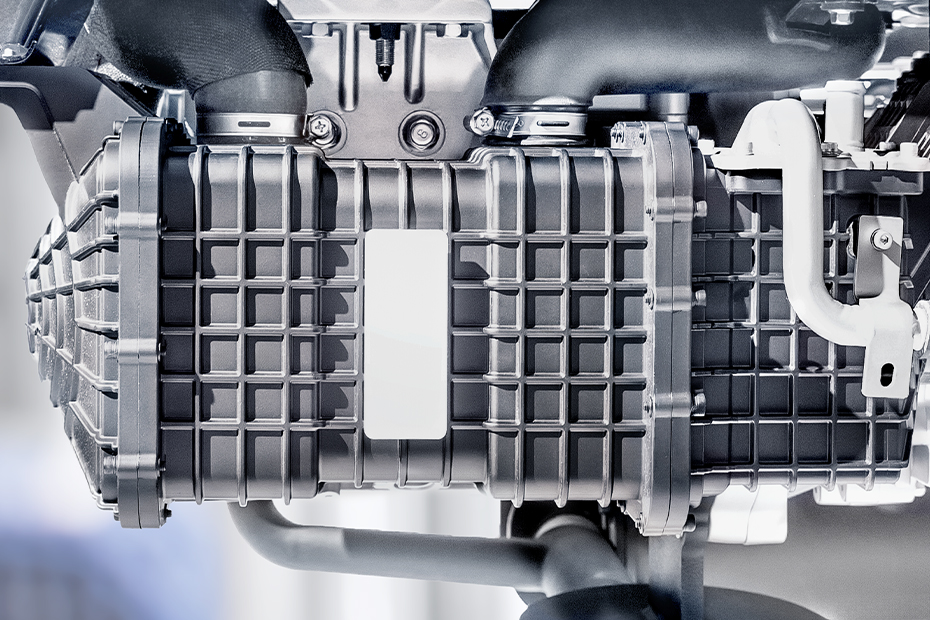

Further epoxy applications: e-motors and distribution networks

Apart from their rail-related applications, Wevo’s potting compounds are also suitable for indoor insulators in distribution networks as well as for the stator potting of electric motors – applications that require high electrical stability through precisely tailored properties to ensure long-term performance. This enables Wevo to support rail, energy technology and electric vehicle manufacturers in the safe, efficient design of high-performance components.